Using metallic embroidery thread is fascinating as it offers a shine and luxury finish to your projects. Their reflective properties can turn a plain and simple design into something extraordinary. However, metallic threads add elegance to the fabric and often come with issues like needle breakage, thread shredding, and skipped stitches. But all your worries will be gone as our guide will aid you in discovering the right approaches for using metallic threads on your embroidery machine, ensuring the best results.

It is therefore important to select the right needle size when using metallic embroidery thread. If you do not have the right tools, your thread and fabric will be damaged and you will not get the required results. Follow our guidelines to address your needs and improve your embroidery projects with flawless stitching.

Here, we are going to enlist embroidery needles compatible for metallic thread.

Best Budget-Friendly

Best Budget-Friendly

Price: $7.39

Read Full Reviews Best Value

Best Value

Price : $7.81

Read Full Reviews Limited Time Deal

Limited Time Deal

-26% $7.40

List Price: $10.04

Limited Time Deal

Limited Time Deal

What Makes Metallic Threads Unique?

Metallic threads are distinct from regular embroidery threads. The thread comprises a nylon or polyester core coated with a metallic foil. This construction gives the thread its glistening sheen but at the same time makes it susceptible to issues like breakage, fraying, and skipped stitches.

The layer of the metallic foil can produce friction as it moves through the fabric thus the metallic threads need to be handled carefully during embroidery. Compared to traditional threads, metallic threads are more fragile and might easily break, especially if the wrong needle size is used when sewing.

The Role of Needle Size in Embroidery

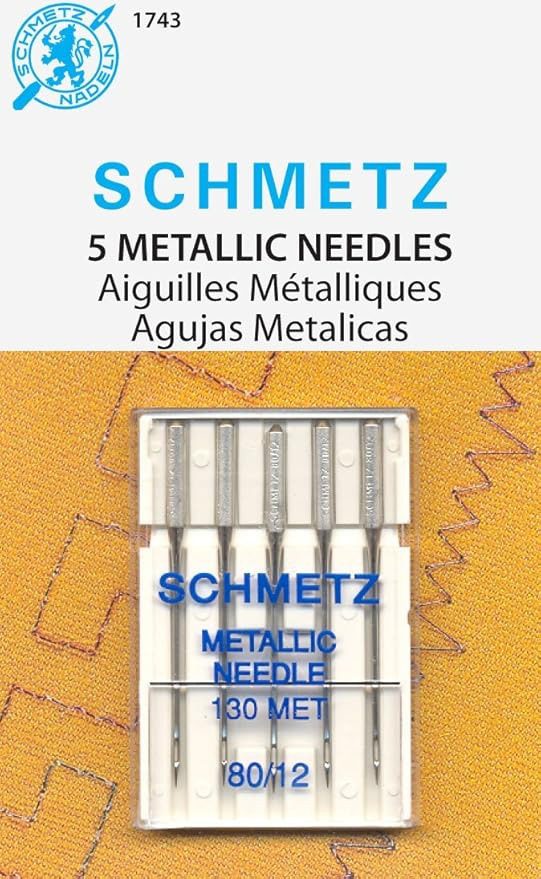

The size of the needle is very important when it comes to embroidery, especially when using metallic threads. Embroidery needle types are available according to their sizes and are usually marked with two figures; 80/12 or 90/14. The first figure is for European size and the second figure indicates the American size. The lower figures therefore represent finer needles which are suitable for thin and delicate fabrics while the higher figures represent thick needles for thick and rough fabrics.

When sewing with metallic threads, it is always advisable to complement the right needle size with the right thread and the right fabric. The proper needle size will decrease tension, prevent the thread from breaking, and produce even stitches on the fabric.

Choosing the right needle size for the metallic threads

For metallic threads, it is recommended to use 80/12 and 90/14 needle sizes. These sizes offer the right balance of thickness and precision so that the thread can slide through fabrics without friction.

80/12 Needle: Recommended for delicate metallic threads and lighter varieties of fabrics. This size minimizes the breakage of the thread, hence preserving the quality of the fine fabric.

90/14 Needle: Recommended for use with thicker metallic threads and dense fabrics. This size gives the extra power required in sewing the tough fabric.

Therefore, in choosing the right needle size, it is important to consider the size of the metallic thread used and the fabric material to be sewn on.

Specialty of Metallic Needles

These special needles are meant to be used with metallic threads. Unlike regular embroidery needles, these needles have a larger eye to help decrease friction so that the metallic thread won’t break or fray while passing through the eye of the needle.

Aside from the increased size of the eye, metallic needles have smooth stainless steel shafts and a Teflon layer coating on the outside to minimize friction. This coating is useful when carrying out embroidery work from materials such as sticky or glue-backed fabrics as the needle does not get gummed up.

When and why to use specialty metallic needles:

- When to Use: When you are using metallic threads especially when designing complex designs or when using thick threads.

- Why to Use: To prevent the threads from breaking and to decrease friction hence producing uniform stitches.

Enhancing Your Embroidery Experience: The Role of Thread Inserts on Metals

Thread inserts or thread guides are also termed spool inserts, which is a small tool that creates a great impact while working with metallic threads. These inserts assist in controlling the flow of the metallic thread by reducing tension and preventing the thread from twining when being fed through the machine.

It is especially advantageous when using metallic embroidery thread because it prevents thread breaks and regulates the flow of the thread insertion. Thread inserts eliminate the stress on the threads hence useful in delivering smooth and even stitches without the hustle of broken threads frequently.

Moreover, if you want to enhance your embroidery experience, you should purchase a high-quality and best embroidery machine from a reputable brand. This will ensure you acquire the required outcome.

Practical tips to work with metallic Threads

It is tricky to work with metallic threads, but following our guidelines ensures you get the best outcome. Here are some additional tips to enhance your embroidery experience.

- Slower Stitching Speed: Slowing down the stitching speed on your embroidery machine reduces the pressure on metallic threads and, as a result, reduces the likelihood of breakage and produces even stitching.

- Loosening Machine Tension: Unlike regular threads, metallic threads are finer, therefore you need to adjust your tension and set it lower than usual. This adjustment minimizes the chances of breakage by enabling the thread to glide along smoothly.

- Using Thread Nets: By using thread nets, it will be easier to manage the pulling out of the metallic thread from the spool so that it will not coil or twist. The use of this simple tool will have a profound impact on the quality of your embroidery work.

- High-Quality Threads: It is essential to understand that not all metallic threads are the same. Using a better quality metallic embroidery thread increases durability and makes the embroidery process a bit easier.

FAQ

For the metallic threads, use needle sizes 80/12 for fine threads and lightweight fabrics and 90/14 size for thick threads and dense fabrics.

You can use ordinary embroidery needles, however, it is recommended to use metallic needles only to achieve the best results. These needles have a larger eye to hold the thread thickness and a non-stick surface to minimize friction and thread breakage.

Thread insert is useful in controlling the flow of metallic threads and preventing them from twisting by reducing tension. Therefore, you get even stitches and minimize the chances of thread breakages.

To avoid breakage, lower the stitching speed and the tension of the machine, or put some thread inserts or nets in between the layers. Further, use a high-quality metallic thread and a metallic needle specialized for this work.

Yes, purchasing high-quality metallic threads from reputable brands helps to improve your embroidery experience.